Midget Movies  Drop Card

Drop Card

|

|

|

|

I found these machine advertised on a local classified page and contacted the seller and then did some research. I decided to purchase the machine for $220 as I was unable to power the machines on

at the time of purchase and the blue and yellow machine was locked. From what little there is on the internet for these machine I have determined that the Midget Movies machine was made by Capitol

Projector Corp back in 1947. The blue and yellow machine I suspect was made around the same time and possibly a year are two earlier. I was told the blue and yellow machine was a kinetoscope, but

after getting the side access door open discovered it is a "Drop Card" machine. Drop Card machines show a single picture for a short period of time and then the next picture drops into place. In this

machine there is a total of 16 cards. After plugged the two machines in and did some minor work, I was able to make the drop card machine function to a very small degree but not the Midget Movies. I did pull the projector component out of the machine and connected power straight to the lamp and the motor and both worked. Since the Drop Card machine was closer to working as designed, I decided to tackle that machine first and Hannah assisted. The photo on the right was take just as we pulled into the driveway. |

|

|

For this machine the wiring and mechanics are pretty simple. There are two lights for the marquee, one on each side. There is a lamp inside the machine that turns on when a coin is inserted. When we first received the machine the marquee lights remained lit anytime the machine was plugged in. As we rewired the machine, we discovered that it was designed to turn off the marquee lights during the viewing process. The machine was pretty dirty and the aluminum/chrome is very pitted and stained. All of the parts appeared to be on the machine and intact. The machine is about 5ft tall complete with the view port about 3 1/2 to 4 feet up. Just right 'For Kiddies'! |

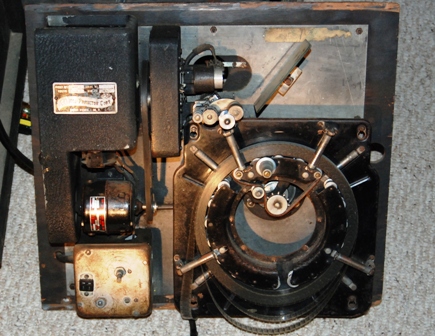

| Once we drilled the lock, we got a chance to examine the mechanism. As you can see in this photo it was extremely dirty and the wiring insulation was just falling off the wires. We learned that there was a magnifing lens just above the drop cards and that the motor is a Klaxon that turned out to be from england and a 220v. What you can't see in the photo is 110v to 220v transformer and the HUGE reostat that is used to regulate the speed of the drops. We decided that a complete rework and rewiring of the machine was be the only way we could feel safe about it running. This machine's cabinet is all metal and a short could become quite exciting! |

|

|

In this close up of the mechanics before the restoration, you can see the mercury switch 'flip / flop' on the lower center/right with the two wires connected to it. Apparently, someone worked on

the machine previously and did some wiring modifications. You can also see on the bottom right the tube and coin strike lever. When a coin is dropped into the machine, it was designed to fall on to

the 'coin strike' lever which in turn flipped the mercury switch to the right thus turning on the machine and the light. |

|

Hannah and I pulled the mechanism assembly from the machine and set it on a work table to begin work. You can see in this photo all the dirt and grime and old grease that was on the machine.

Since we knew the wiring was bad, I examined the system and then drew up what I thought was a correct wiring diagram for it. I took a few more detail photos and we then tore it all down. The only

parts we did not remove was the motor, the reel assembly and the 220v transformer and reostat. We cleaned it all up removing all the old grease then as we re-assembled it we applied a bit of white

lithium grease to the moving parts. I realized that since there were two mecury switches that 'flip flopped' I figured one must be for the motor and viewing lamp and the other for the marquee lamps.

On this machine, the view port does not have a visor around it so if the marquee lights are not switched off during the viewing it would hamper your ability to see the images.

|

|

|

After 7 plus hours of work, the mechanics were all cleaned, lubricated and put back into position. All the wiring has been replaced and the mercury switches connected as originally designed.

Hannah also cleaned each drop card as there were very dirty and luckily they are laminated cards so cleaning was easy with Windex and paper towels. When we reinstalled the assembly into the cabinet

we installed it correctly with support bolts which allows for the coin box to be easily removed. Previously, the supporting bolts were missing and the assembly just sat on the coin box. Now that it is all installed, the machine is working as it should. However, the coin shoot is missing and I will have to fabricate one along with a slug rejector. The new wires are a bit stiffer than the old wires and that is preventing the flip flop switch from moving as easily as it should. But these two issures are the only ones remaining to complete the machine. Currently we can make it work by pressing the coin strike lever by hand. I am working on documentation for this machine and will be posting it here. I searched the Internet and could not find any documentation so hopefully this documentation will help others with the same machine. |

|

I got to spend a little more time with the machine and got it working as it should and with a coin drop to boot! There were several issues preventing the flip flop switch from functioning

corretly. One was the wires were too tight through the swivel hole so I moved one of them (brown) out of the hole and that helped. Also, I adjusted the snap spring so it excerted a bit more pull

one the switch. But the biggest was the change to the location of the cam arm that regulates the location of the reel in comparison to the rest of the components. With the machine functioning as

is should my efforts then turned to the coin slot. I went to Ace Hardware and picked up a new cabinet lock and while I was there I looked in the electrical department and found a plastic 'cable guide / hide-a-wire' that was about 4ft in length. I borrowed a nickel from the cashier and discovered that a nickel fit perfectly down the center. Once I got it home, I trimed up one end to fit over the coin slot and the cut it to length. The coin slot end fit tightly but to insure it doesn't come off, I used a zip-tie to snug it up. Dropped and coin through the slot and it worked perfectly. I then replaced the cabinet lock and said 'Done.'. |

|

|

|

|

The second machine to tackle is the Midget Movies. Since the lamp and motor tested good, I figured the only thing left to do was clean up the mechs and look for any broken wires and/or components.

This machine is designed to have to 'featurettes' that will play for one dime each. The film is on a continous loop just like the old 8-track tapes were back in the day. Currently the film is a

Mickey Mouse cartoon with Plute and a short appearance by Minnie. This machine is made by the Capitol Projector Corp. and I am estimating it to have been manufactored around 1947. Originally designed for the Arcades, they had a difficult time becoming a profit make enterprise. Some were moved to the carnival and other 'boardwalk amusement parks' and placed where the patrons were standing in lines to capture revenue there and provide some entertainment while the parks customer's waited. |

|

|

After finding only minimal revenue in the arcades, some of the machines (and it appears mine is one of them) were used for adult 'peep show' movies. Micah was helping me with this machine and as

we were cleaning we pulled the marquee ads out and behind the Mickey pictures were the bathing beauties! The lady on the right had her name on the reverse side of the photo and through some internet

research we discovered she had a role in the movie Oklahoma and a guest appearance on Murder She Wrote. I am assuming that the films presented with these ladies were most likely G rated with a slight

possiblity of being 'PG'. Micah thought they were cool! After examining the projector and other components, I determined the only way to get the machine working as it should would be to completely disassemble the projector and refurbish it. It's a good thing too, the film tracks were caked with old dirt, oil and gunk. |

| In this photo Ninja is checking out the projection system. Above him and the right you can see the coin box that is opened. To the left is the duct work to help vent the heat from the lamp to the side of the machine. You can also see the main power connections and fuse component. On the door you can see the coin mech which is a dime sliding type by ABT Mfg. |

|

|

The machine is designed in such a manner that allows the projection and feel holder to be removed by simply sliding it out the front door. This makes access to the projector and loading of the film

possible. This photo was taken when we first pulled out the projection board and you can see the dirt, grime and broken film on it. The Lamp is behind the black box on the upper left, the projector is in the center upper and the reflection mirror is to the right. Above this mirror is a semi-translucent plastic that serves as the viewing screen. This plastic was in horrible shape so I found a semi-clear plastic folder as the dollar store and fashioned a new viewing screen. |

|

Pulling out the projector, Micah and I dissassmbled the projector. In this photo you can see the various parts of the projector ready for cleaning and resassembly. This process took us 2 to 3 hours

alone but it really made a difference in the performance of the projector. Once we cleaned up the projector and re-installed it on the assembly board, we then cleaned and repaired the one bad roller on the

film holder. I used some very light weight oil to lubricate the projector and fil reel wheels. Currently the machine is working 95% although it difficult for it to sense the stop points in the film reliably. I will post more photos soon containging after shots of the complete project. |

|

|

Digging into the electrical components I was determined to find out why the machine would not function. Since the motor and lamp test good, I figured it had to be in the wiring or switching components. In the lower left of this photo you can see the control book opened up with the circular reostate and one large multi switch solinoid. As suspected, between the bad wiring and a mis-adjusted end of film switch these were keeping the machine from working. |

| The photo to left is a bit difficult to see, but I took this while the movie was running through the view port. You can see Mickey but when you are looking through the view port the image is better and you can see more of the image. |

|